Video

See what makes Barger And Sons unique

See what makes Barger And Sons unique

Precast-IT!

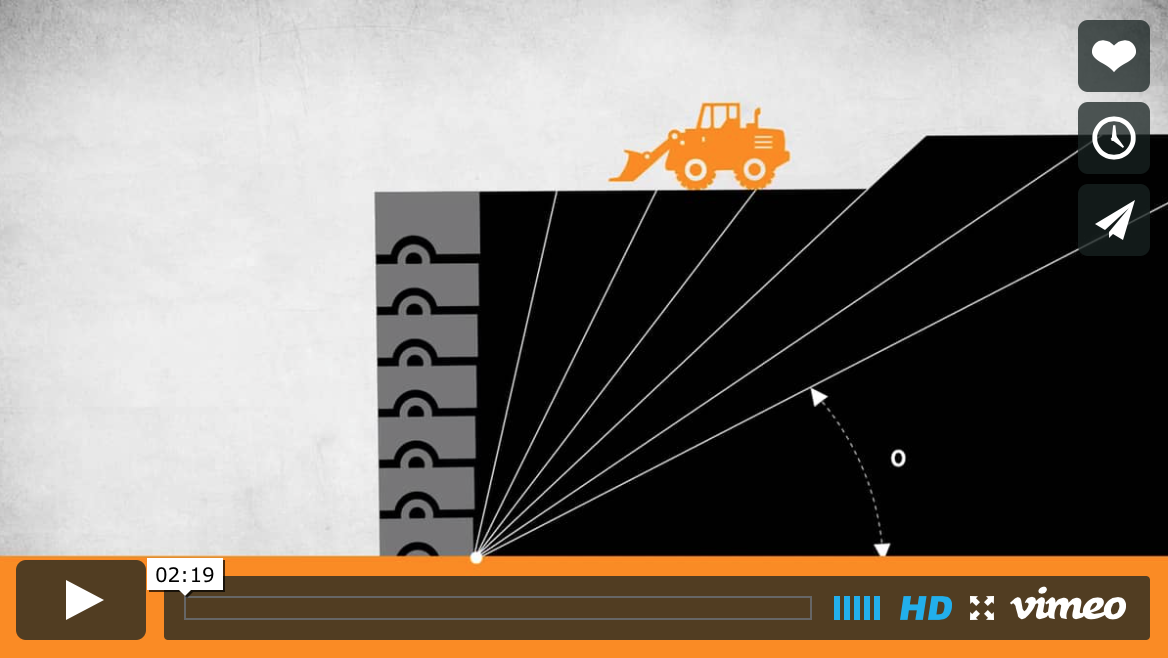

Precast-IT! makes it possible to provide the best possible products at the lowest possible prices. By tracking inventory levels on a daily basis with 99.99% error free mistakes means that we know what to produce and when. By having an Inventory Management System that maintains a record of raw material characteristics, concrete cylinder breaks, inventory levels and age of each product line in stock, to the time, date, and delivery specialist who delivered the product eliminates product defects and keeps inventory levels low. This means we don't have to have large inventory levels and are able to deliver certified product just-in-time for your project. This passes the savings on to you.

Currently, Barger & Sons, Inc. is the only precast concrete company in the United States that utilizes Precast-IT! for their Inventory Management System.

Precast-IT! makes it possible to provide the best possible products at the lowest possible prices. By tracking inventory levels on a daily basis with 99.99% error free mistakes means that we know what to produce and when. By having an Inventory Management System that maintains a record of raw material characteristics, concrete cylinder breaks, inventory levels and age of each product line in stock, to the time, date, and delivery specialist who delivered the product eliminates product defects and keeps inventory levels low. This means we don't have to have large inventory levels and are able to deliver certified product just-in-time for your project. This passes the savings on to you.

Currently, Barger & Sons, Inc. is the only precast concrete company in the United States that utilizes Precast-IT! for their Inventory Management System.